DALIAN MACH CO.,LTD is one of leading manufacturer of torno CNC lathe,Vertical Machining Center, etc in China

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Color: | |

|---|---|

| Quantity: | |

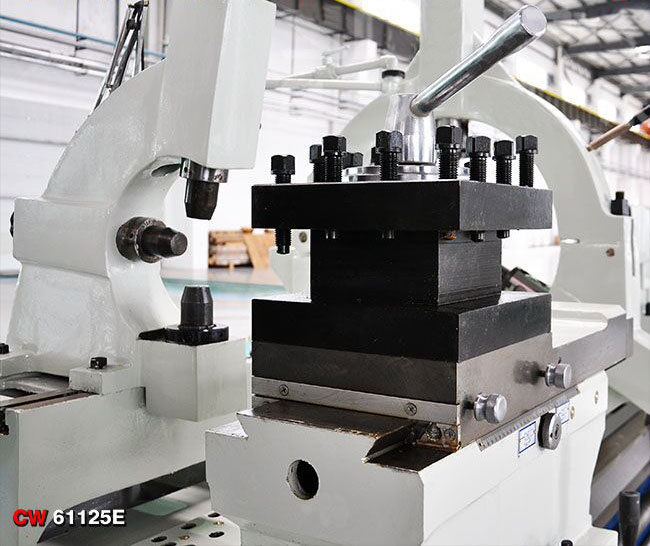

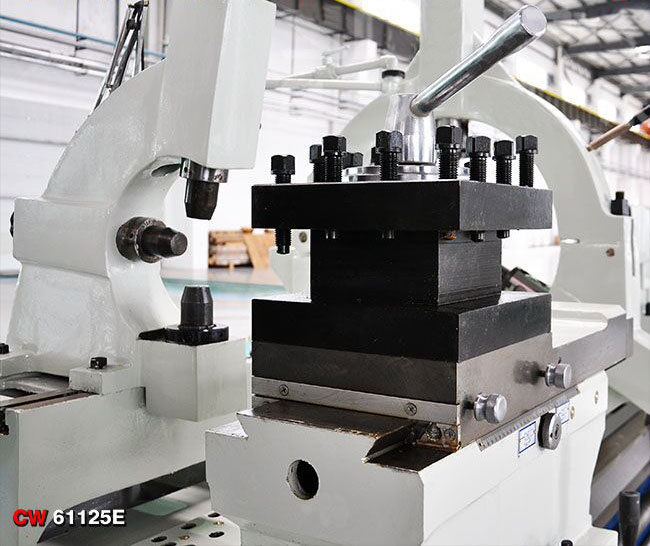

CW61125E

MACH

| MODEL | CW61125E |

| Swing over bed | 1,250 mm |

| Max. Swing over carriage | 900 mm |

| Distance between centers | 2000 mm, 3000mm, 5000mm |

| Max. Length to be turned | 4,800 mm |

| Bedways width | 755 mm |

| Max. Supporting weights of centers | 8,000 kg |

| Spindle nose | iso a2-15 |

| Spindle bore | 130 mm |

| Spindle speeds | 3.15 to 315 rpm, 21 step |

| Number of feeds and ranges | 56 |

| Longitudinal | 0.1 to 12 mm |

| Cross slide | 0.05 to 6 mm |

| Compound slide | 0.025 to 3 mm |

| No. & range of metric threads | 56 kinds, 1-120 mm |

| No. & range of inch threads | 56 kinds, 30-1/4 t.p.i. |

| No. & range of module threads | 56 kinds, 0.5-60 |

| No. & range of diametric pitch’s | 56 kinds, 60-0.5 |

| Max. Travel of cross slide | 680 mm |

| Max. Travel of compound | 300 mm |

| Dia. Of tailstock sleeve | 200 mm |

| Taper of tailstock sleeve | Morse no.6 |

| Max. Movement of tailstock sleeve | 300 mm |

| Power of main motor | 22 kw |

| Power of rapid motor | 1.5 kw |

| Power of pump motor | 0.55 kw |

| Power of cooling motor | 0.15 kw |

| Electrical power | as user’s need |

| Net overall dimension of the machine | 6,100×1,875×1,915 mm |

| Packing dimension of the machine | 6,360×1,950×2,280 mm |

| N. W. / G. W. | 13,550 / 15,760 kgs |

Quality is our forte and we have clients spreading all over the world. We are committed to a well-defined and self-framed quality policy. The policy revolves around through and repeated checking of the heavy duty lathe. We are the regular exporters of our products throughout Asia, Africa and several European countries. Our after-sales service terms and conditions as follows:

| MODEL | CW61125E |

| Swing over bed | 1,250 mm |

| Max. Swing over carriage | 900 mm |

| Distance between centers | 2000 mm, 3000mm, 5000mm |

| Max. Length to be turned | 4,800 mm |

| Bedways width | 755 mm |

| Max. Supporting weights of centers | 8,000 kg |

| Spindle nose | iso a2-15 |

| Spindle bore | 130 mm |

| Spindle speeds | 3.15 to 315 rpm, 21 step |

| Number of feeds and ranges | 56 |

| Longitudinal | 0.1 to 12 mm |

| Cross slide | 0.05 to 6 mm |

| Compound slide | 0.025 to 3 mm |

| No. & range of metric threads | 56 kinds, 1-120 mm |

| No. & range of inch threads | 56 kinds, 30-1/4 t.p.i. |

| No. & range of module threads | 56 kinds, 0.5-60 |

| No. & range of diametric pitch’s | 56 kinds, 60-0.5 |

| Max. Travel of cross slide | 680 mm |

| Max. Travel of compound | 300 mm |

| Dia. Of tailstock sleeve | 200 mm |

| Taper of tailstock sleeve | Morse no.6 |

| Max. Movement of tailstock sleeve | 300 mm |

| Power of main motor | 22 kw |

| Power of rapid motor | 1.5 kw |

| Power of pump motor | 0.55 kw |

| Power of cooling motor | 0.15 kw |

| Electrical power | as user’s need |

| Net overall dimension of the machine | 6,100×1,875×1,915 mm |

| Packing dimension of the machine | 6,360×1,950×2,280 mm |

| N. W. / G. W. | 13,550 / 15,760 kgs |

Quality is our forte and we have clients spreading all over the world. We are committed to a well-defined and self-framed quality policy. The policy revolves around through and repeated checking of the heavy duty lathe. We are the regular exporters of our products throughout Asia, Africa and several European countries. Our after-sales service terms and conditions as follows: