DALIAN MACH CO.,LTD is one of leading manufacturer of torno CNC lathe,Vertical Machining Center, etc in China

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

CKE6180Z

DMTG

5458.1100

CKE6180Z Dalian DMTG Economic Horizontal Torno CNC Lathe

1. Construction casting molded with resin sand of bed, headstock, saddle plinth, ect;

2. Turcite-B coated on mating surfaces between saddle and guideways;

3. Precision ballscrew, high rigidity precision compound bearings ensure accurate positioning and efficient driving of cnc lathe. Centralized oil lubricator providing forced automatic lubrication onto ballscrew, mating surfaces;

4. High spindle speed with wide variable speed ranges. Low noise 80db, CKE-Zseries cnc lathe machine adopting the smart automatic gear changing mechanism enables automatic speed changes among low, medium, high speed ranges without turning off the cnc lathe machine. CKE-i series cnc lathe machine with independent spindle strcture and frequency converted motor or servo motor enables high spindle speed and stepless spindle changing;

5. Flexible control panel enables convenient tool setting for the cnc lathe;

6. Popular full enclosed guards with interlock offer a waterproof and chip-free environment;

7. Vertical 4-position toolpost, horizontal 6-position toolpost, quick change toolpost, etc are available for your selection for this cnc lathe machine;

8. Optional, pneumatic, hydraulic chuck and tailstock are available for this cnc lathe machine;

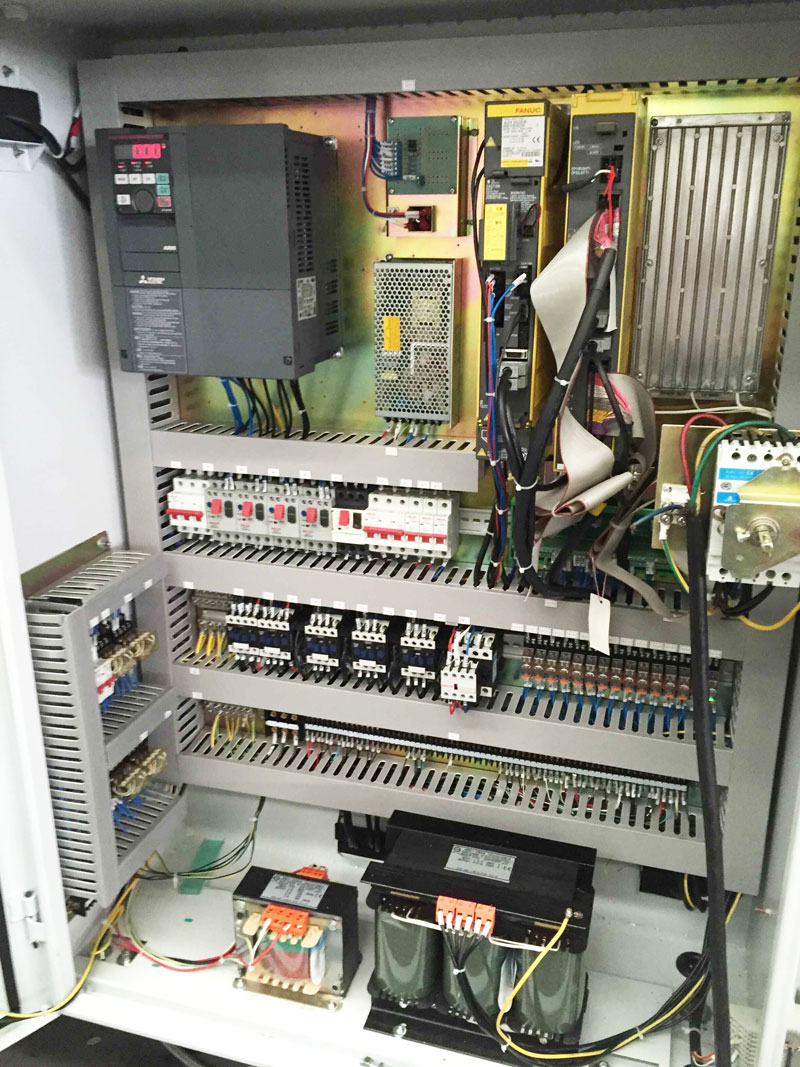

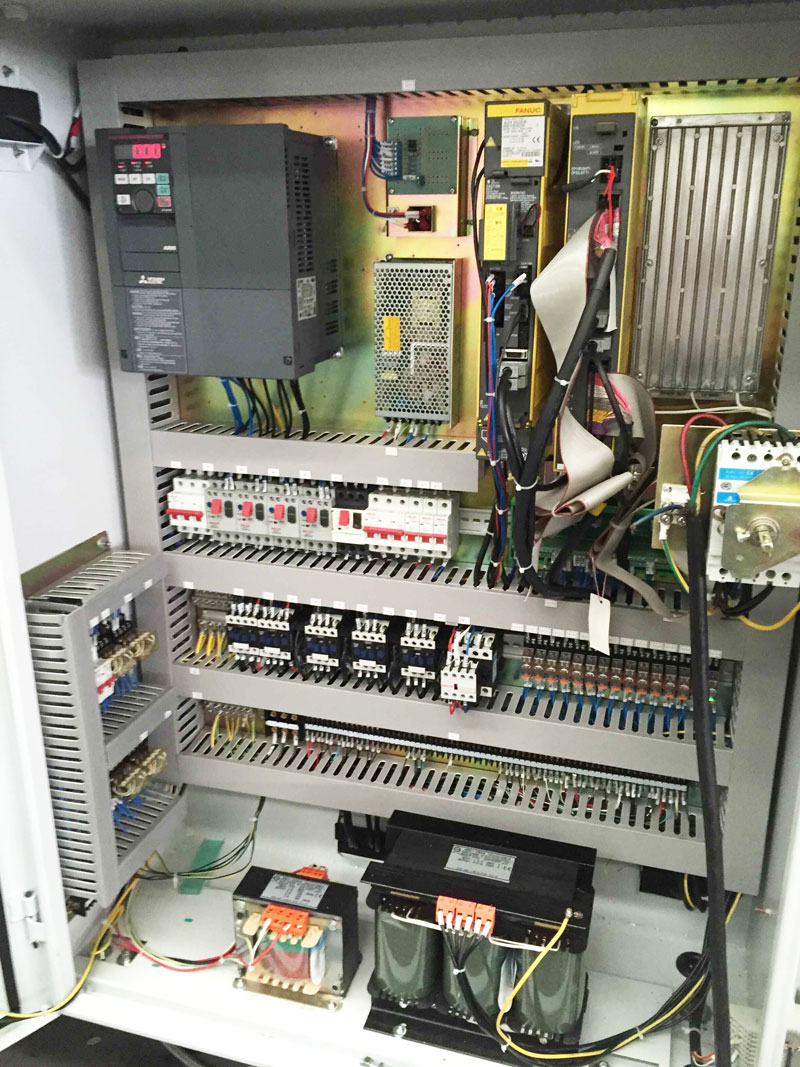

9. FANUC, SIEMENS, etc control systems can be appointed E-handwheel function can also be equipped.

Model: CKE6180Z

Capacity: | Metric | Inch | |

X-axis Travel | 420mm | 16.5” | |

Z-axis Travel | 785/1235/1835/2735/3735/ 4735mm | 30.9”/48.6”/72.2”/107.7” /147” /186.4” | |

Swing Over Bed | 800mm | 31.5” | |

Swing Over Cross Slide | 490mm | 19.3” | |

Maximum Turning Diameter | 800mm | 31.5” | |

Maximum workpiece length | 1000/1500/2000/3000/4000 /5000 mm | 40”/59”/78.74”/118.1” /157.5” /196.9” | |

Spindle: | |||

Spindle Nose | D11 | ||

Spindle Speed Range | 40 – 178 / 71 – 310 / 124 – 556 / 222 - 1000 RPM

| ||

A.C. Spindle Motor (1 min.) | 11 KW | 15 HP | |

Chuck Size | 400mm | 16” | |

Spindle Bore Diameter | 100mm | 3.9” | |

Motion: | |||

X-axis Rapid Feed Rate | 4000 mm/Min | 160 IPM | |

Z-axis Rapid Feed Rate | 8000 mm/Min | 315 IPM | |

Turret | |||

Number of Stations | 4 station vertical turret | ||

Index Time (Adjacent) | 2.9 seconds | ||

Turret Accuracy | .008 | .0003” | |

Tool Shank Width | 40 | 1.5” | |

Tailstock | |||

Dia. Of quill | 100 mm | 3.94” | |

Quill travel | 240 mm | 9.45” | |

Quill taper | MT.6 | MT.6 | |

Machine Dimensions: | |||

Overall length | 3455/4010/4510/5410/6455/ 7535 9820/10820/12820 mm | 136”/158”/178”/213” /254”/296.7” | |

Overall width | 2000mm | 78.7 | |

Overall height | 1800mm | 70.9” | |

Machine Weight | |||

D.B.C 1000mm | 5200kg | 11465 lbs | |

D.B.C 1500mm | 5300kg | 11685 lbs | |

D.B.C 2000mm | 5800kg | 12790 lbs | |

D.B.C 3000mm | 6100kg | 13450 lbs | |

D.B.C 4000mm | 7600kg | 16720 lbs | |

D.B.C 5000mm | 8600kg | 18920 lbs | |

Door interlock |

Chuck guard with switch |

CE electrics |

Elecric Hand wheel (Two ) and manual start-up joystick |

4 jaw chuck diameter: 630mm |

Horizontal 8-Station Turret ( coolant through ) |

400mm hydraulic chuck (through-hole) |

Hydraulic tailstock for CKE6180 |

Hydraulic station for CKE6180 |

Steady rest Dia:40-250mm |

Steady rest Dia:150-450mm |

Live Center M6 for CKE6180 |

Anti-vibration pads (1 set) |

Germany type quick change toolpost to replace standard 4 station electric turret |

Quality is our forte and we have clients spreading all over the world. We are committed to a well-defined and self-framed quality policy. The policy revolves around through and repeated checking of the lathe cnc. We are the regular exporters of our products throughout Asia, Africa and several European countries. Our after-sales service terms and conditions as follows:

The lathe cnc are tested and have trial production in our factory before leaving our factory and they are shipped out only after the customers are satisfied with them.

When the lathe cnc are tested, our technicians will train the customers’ technicians in theory and practice till they grasp the skills.

During this period of one year warranty , if the lathe cnc were damaged by non-artificial reasons, we are responsible for repairing or changing parts.

During this period of warranty, if there is something wrong with the lathe cnc, we are responsible to provide project for solving this problem at the soonest, and help customers to restore production as soon as possible.

After the warranty, we charge only cost price for maintaining the lathe cnc within three years.

Other after-sale terms can be agreed by buyer and seller in addition.

CKE6180Z Dalian DMTG Economic Horizontal Torno CNC Lathe

1. Construction casting molded with resin sand of bed, headstock, saddle plinth, ect;

2. Turcite-B coated on mating surfaces between saddle and guideways;

3. Precision ballscrew, high rigidity precision compound bearings ensure accurate positioning and efficient driving of cnc lathe. Centralized oil lubricator providing forced automatic lubrication onto ballscrew, mating surfaces;

4. High spindle speed with wide variable speed ranges. Low noise 80db, CKE-Zseries cnc lathe machine adopting the smart automatic gear changing mechanism enables automatic speed changes among low, medium, high speed ranges without turning off the cnc lathe machine. CKE-i series cnc lathe machine with independent spindle strcture and frequency converted motor or servo motor enables high spindle speed and stepless spindle changing;

5. Flexible control panel enables convenient tool setting for the cnc lathe;

6. Popular full enclosed guards with interlock offer a waterproof and chip-free environment;

7. Vertical 4-position toolpost, horizontal 6-position toolpost, quick change toolpost, etc are available for your selection for this cnc lathe machine;

8. Optional, pneumatic, hydraulic chuck and tailstock are available for this cnc lathe machine;

9. FANUC, SIEMENS, etc control systems can be appointed E-handwheel function can also be equipped.

Model: CKE6180Z

Capacity: | Metric | Inch | |

X-axis Travel | 420mm | 16.5” | |

Z-axis Travel | 785/1235/1835/2735/3735/ 4735mm | 30.9”/48.6”/72.2”/107.7” /147” /186.4” | |

Swing Over Bed | 800mm | 31.5” | |

Swing Over Cross Slide | 490mm | 19.3” | |

Maximum Turning Diameter | 800mm | 31.5” | |

Maximum workpiece length | 1000/1500/2000/3000/4000 /5000 mm | 40”/59”/78.74”/118.1” /157.5” /196.9” | |

Spindle: | |||

Spindle Nose | D11 | ||

Spindle Speed Range | 40 – 178 / 71 – 310 / 124 – 556 / 222 - 1000 RPM

| ||

A.C. Spindle Motor (1 min.) | 11 KW | 15 HP | |

Chuck Size | 400mm | 16” | |

Spindle Bore Diameter | 100mm | 3.9” | |

Motion: | |||

X-axis Rapid Feed Rate | 4000 mm/Min | 160 IPM | |

Z-axis Rapid Feed Rate | 8000 mm/Min | 315 IPM | |

Turret | |||

Number of Stations | 4 station vertical turret | ||

Index Time (Adjacent) | 2.9 seconds | ||

Turret Accuracy | .008 | .0003” | |

Tool Shank Width | 40 | 1.5” | |

Tailstock | |||

Dia. Of quill | 100 mm | 3.94” | |

Quill travel | 240 mm | 9.45” | |

Quill taper | MT.6 | MT.6 | |

Machine Dimensions: | |||

Overall length | 3455/4010/4510/5410/6455/ 7535 9820/10820/12820 mm | 136”/158”/178”/213” /254”/296.7” | |

Overall width | 2000mm | 78.7 | |

Overall height | 1800mm | 70.9” | |

Machine Weight | |||

D.B.C 1000mm | 5200kg | 11465 lbs | |

D.B.C 1500mm | 5300kg | 11685 lbs | |

D.B.C 2000mm | 5800kg | 12790 lbs | |

D.B.C 3000mm | 6100kg | 13450 lbs | |

D.B.C 4000mm | 7600kg | 16720 lbs | |

D.B.C 5000mm | 8600kg | 18920 lbs | |

Door interlock |

Chuck guard with switch |

CE electrics |

Elecric Hand wheel (Two ) and manual start-up joystick |

4 jaw chuck diameter: 630mm |

Horizontal 8-Station Turret ( coolant through ) |

400mm hydraulic chuck (through-hole) |

Hydraulic tailstock for CKE6180 |

Hydraulic station for CKE6180 |

Steady rest Dia:40-250mm |

Steady rest Dia:150-450mm |

Live Center M6 for CKE6180 |

Anti-vibration pads (1 set) |

Germany type quick change toolpost to replace standard 4 station electric turret |

Quality is our forte and we have clients spreading all over the world. We are committed to a well-defined and self-framed quality policy. The policy revolves around through and repeated checking of the lathe cnc. We are the regular exporters of our products throughout Asia, Africa and several European countries. Our after-sales service terms and conditions as follows:

The lathe cnc are tested and have trial production in our factory before leaving our factory and they are shipped out only after the customers are satisfied with them.

When the lathe cnc are tested, our technicians will train the customers’ technicians in theory and practice till they grasp the skills.

During this period of one year warranty , if the lathe cnc were damaged by non-artificial reasons, we are responsible for repairing or changing parts.

During this period of warranty, if there is something wrong with the lathe cnc, we are responsible to provide project for solving this problem at the soonest, and help customers to restore production as soon as possible.

After the warranty, we charge only cost price for maintaining the lathe cnc within three years.

Other after-sale terms can be agreed by buyer and seller in addition.